Coatings Innovation

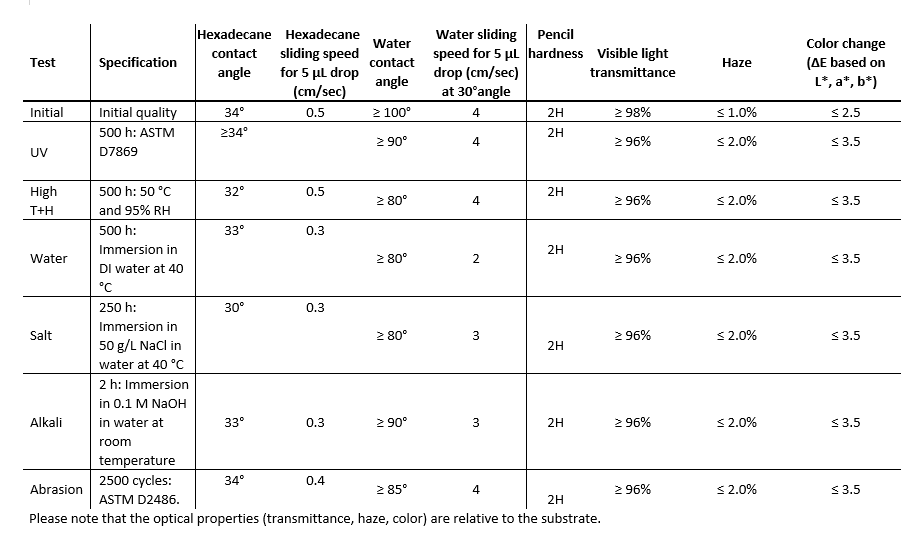

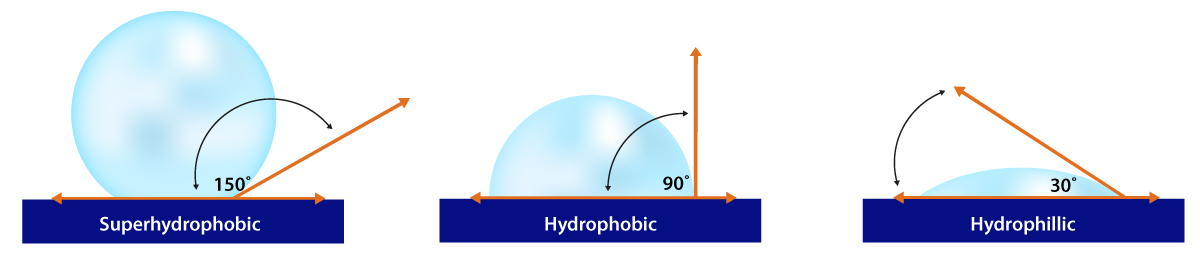

Hydrophobic coatings are characterized by surfaces that encourage beading up of water, such that a simple tilt of the surface, or a gentle swipe of a rag across the surface can easily remove the water without the need for detergents or additional cleaning agents. The degree of hydrophobicity is generally determined as a function of the contact angle that the water makes with the surface (See figure below) and can be further characterized by the speed at which the water droplet runs off the surface when held at a certain angle.

Historically, hydrophobic coatings are created with fluorinated materials, which requires the use harmful Poly- and perfluoroalkyl substances (PFASs). There has recently been activity amongst manufacturers of such coatings to create non-fluorinated versions. Initial attempts to create such coatings with polyurethane formulations often leads to hazy or clouded coatings due to the complex chemistry and interactions between additives that are used to improve mechanical properties including wear and adhesion. Specifically, the vastly different Hansen solubility parameters of the water-repellent additives and the polar polyurethane matrix can create difficulties in creating formulations that result in coatings with ideal qualities of optical clarity, hydrophobicity, adhesion and wear. Thus, their use in industrial applications has been limited to those that do not require a clear coating.

SCOPS unique chemistry allows non-fluorinated coatings to be created by using an amine-based additive in polyurethane formulations. By paying special attention to the specific combinations of additives, SCOPS has been able to produce coatings that exhibit superhydrophobicity and optical clarity.

Selected Test Results