The Problem We Solve

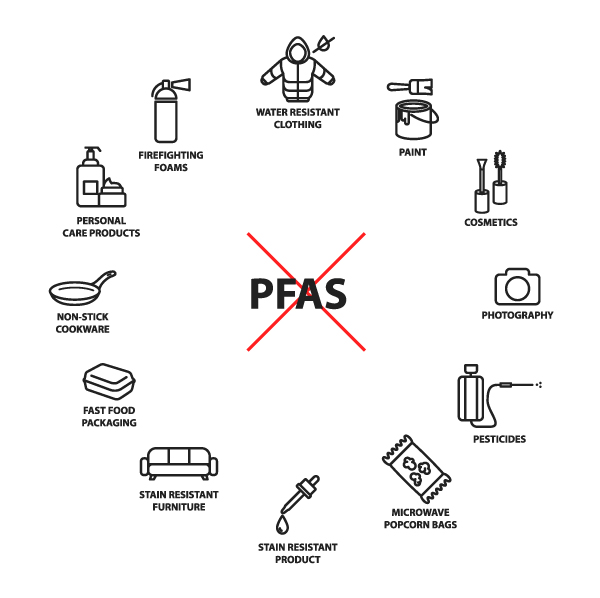

PFAS base coatings are an environmental and health risk. They are called the forever chemical and bioaccumulate causing significant health issues. Substitute omniphobic coatings suffer from many shortcomings including:

SCOPS solves this problem by creating a durable coating using a polyurethane backbone. SCOPS additive can be used in most solvent based 2K polyurethanes with little modification and leverages the vast technology and infrastructure already established for the polyurethane market. By using a polyurethane backbone a separate Omniphobic coating is not needed saving significant cost. Additionally, polyurethane is already used in many applications and can be implemented easily in almost any setting. If polyurethane is already being used no change to the application process will be required.

Who We Serve

PFAS Replacement

Companies that want to replace their current PFAS based coating. PFAS called “the forever chemical” is under legislative scrutiny and will most likely see additional regulations if not a full ban. Scops product can replace most PFAS coating with similar characteristics.

Coating Manufacturers

Coating manufacturers that want to extend their product line with omni-phobic coatings. With several easy-to-use additives most 2k polyurethanes, epoxies and polyaspartics can add an omni-phobic properties.

Polyurethane Coating Enhancement

Companies currently using polyurethane coatings that want to upgrade the surface of their product. SCOPS additives works with most 2K solvent base polyurethanes with little modification. Adding SCOPS’ additive to the polyurethane adds little cost but creates significant perceived value.

Example Markets

Example Applications

Protective coating

- for corrosion

- coil products

- corrugated steel

- automotive topcoat

- heavy equipment

Easy/self- clean coating

- building products

- windows

- coil products

- siding

- gutters

- corrugated steel

- metal roofs

- shower doors

- flooring

- decks

- ceramic fixtures

- granite counters

Anti-graffiti

- Commercial

- Municipal

Antifouling coating

- cooling towers

- HVAC

- Food and beverage industries

Anti-Ice -Tires

Infrastructure protection

Industrial

Heavy Equipment

Automotive

Manufacturing

Flooring